- +91 8055996347

- info@3dreality.in

- Chapru nagar square, CA road, Nagpur, Maharashtra-440008

In today’s fast-paced and competitive market, companies are under pressure to develop, test, and launch products faster than ever. This is where rapid prototyping plays a transformative role. It streamlines the product development cycle, helping businesses save time, reduce costs, and deliver more refined products to market.

In this blog, we’ll explore what rapid prototyping is, and how it significantly accelerates product development.

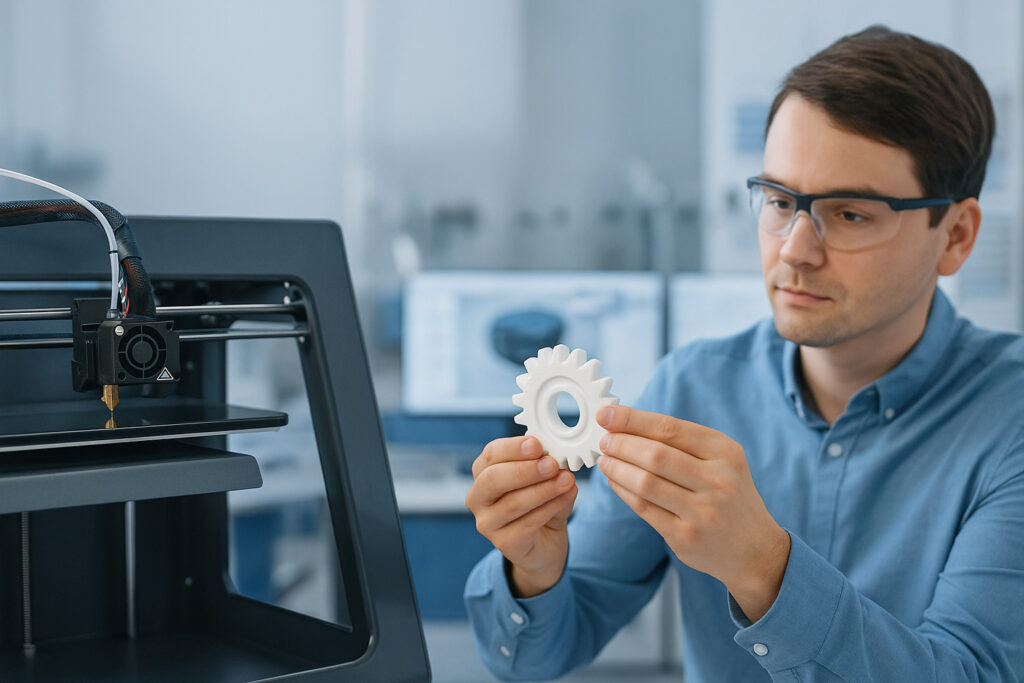

Rapid prototyping is the process of quickly fabricating a physical model or part using 3D printing or additive manufacturing technologies. It allows designers and engineers to create a working prototype of a product concept in a matter of hours or days, rather than weeks or months.

This prototype can be used to test form, fit, function, and user interaction – enabling faster iteration and improvements.

Traditional product development requires tooling and molds, which are time-consuming and expensive to modify. With rapid prototyping, teams can:

This rapid feedback loop reduces the risk of design errors and speeds up the entire process.

By eliminating the need for expensive molds and tooling early in the development phase, rapid prototyping:

For startups and SMEs, this cost-efficiency can make innovation more accessible.

Functional prototypes allow for real-world testing. This means:

Physical prototypes make it easier to communicate ideas:

By streamlining design, testing, and approval processes, rapid prototyping significantly reduces time-to-market. This allows companies to:

Rapid prototyping is widely used in various sectors:

In an age where speed and adaptability define success, rapid prototyping gives businesses a competitive edge. It accelerates product development, reduces costs, improves collaboration, and shortens the feedback cycle.

Whether you’re a large manufacturer or a budding entrepreneur, investing in rapid prototyping can transform the way you develop products — helping you go from idea to launch faster and smarter.