- +91 8055996347

- info@3dreality.in

- Chapru nagar square, CA road, Nagpur, Maharashtra-440008

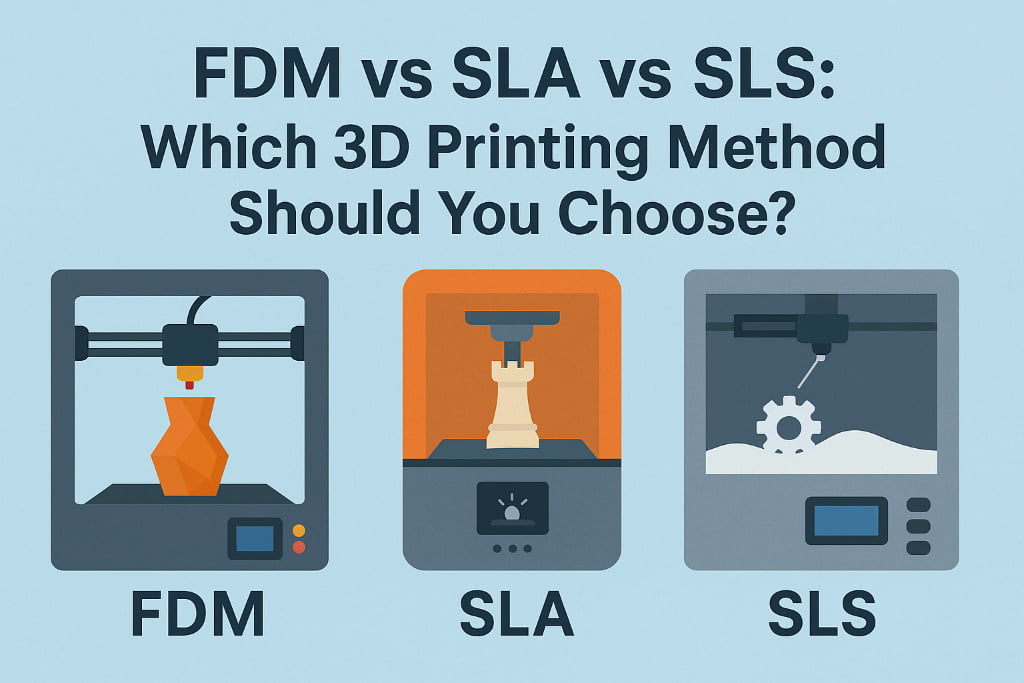

Imagine standing in front of a sleek, humming 3D printer, holding the power to bring any idea to life—layer by layer. Now, here’s the twist: the quality, durability, and cost of that final product depend heavily on one key decision—the type of 3D printing method you choose.

With so many acronyms thrown around—FDM, SLA, SLS—you might feel like you’re picking blindly. But don’t worry. By the end of this article, you’ll not only understand the differences but know exactly which one suits your needs best.

Let’s start the journey through the world of 3D printing.

Fused Deposition Modeling (FDM) is probably the first image that pops into your head when someone mentions 3D printing. Why? Because it’s the most accessible and widely used method.

How it works:

A heated nozzle melts thermoplastic filament (like PLA or ABS), laying it down layer by layer to build the object.

Why choose FDM?

But here’s the catch—while FDM is affordable, it’s not always pretty. Layer lines are visible, and fine details may get lost. If you’re printing something for show-and-tell, this might not be your best bet.

Use FDM when: You’re prototyping, learning, or need functional parts fast and cheap.

Now picture something smoother, shinier, and more detailed. That’s Stereolithography (SLA).

How it works:

Instead of melting plastic, SLA uses a laser to cure liquid resin, solidifying it layer by layer with incredible precision.

Why choose SLA?

But beware—SLA isn’t the cleanest process. Resin is messy, smelly, and needs post-curing. Plus, it can get expensive with time.

Use SLA when: You need precision, surface quality, or intricate detailing.

And then comes the silent powerhouse—Selective Laser Sintering (SLS).

How it works:

A laser fuses powdered material (usually nylon) layer by layer. Unlike FDM or SLA, there’s no need for support structures, thanks to the surrounding powder acting as natural support.

Why choose SLS?

But here’s the surprise—SLS printers are bulky and expensive. They’re not for your garage—they’re for your lab or industrial setup.

Use SLS when: You need tough, functional prototypes or low-volume manufacturing.

|

Feature |

FDM | SLA | SLS |

|

Detail Quality |

Moderate | High |

High |

|

Surface Finish |

Rough | Smooth |

Matte |

|

Cost |

Low | Medium |

High |

|

Speed |

Moderate | Moderate |

Fast (batch) |

| Best For | Prototyping, DIY | Models, Miniatures |

Functional Parts, Production |

Ask yourself:

And if you’re still unsure or need customized advice, 3dreality.in is here to help you choose the perfect method for your project. Whether it’s decorative gifts, mechanical parts, or stunning models—we’ve got the tools and tech to bring your vision to life.

The beauty of 3D printing isn’t just the machines—it’s in the choices. With FDM, SLA, and SLS, the possibilities are endless. Each method unlocks a different creative path.

So next time you’re about to click “print,” pause and ask: What story do I want this object to tell?

Because when it comes to 3D printing—how you print is just as important as what you print.