- +91 8055996347

- info@3dreality.in

- Chapru nagar square, CA road, Nagpur, Maharashtra-440008

In the fast-evolving world of 3D printing, enthusiasts and engineers alike are constantly asking: Can you 3D print electrical components with resin? The short answer? Yes, but with limits.

Let’s explore how far resin 3D printing can go when it comes to making electrical components — what’s possible, what’s not, and where the future is heading.

Resin 3D printing — also known as SLA (Stereolithography), DLP (Digital Light Processing), or LCD printing — is known for its high precision and smooth surface finish. It’s commonly used for miniatures, dental models, jewelry prototypes, and engineering parts.

Unlike FDM printers that melt plastic filament, resin printers use light to cure liquid photopolymer resins layer by layer. This allows for incredibly fine details, making it perfect for small enclosures or parts that need tight tolerances.

But here’s the catch: most standard resins aren’t electrically conductive. So what does that mean for printing actual electrical components?

Before diving into what resin can do, let’s break down the types of electrical components:

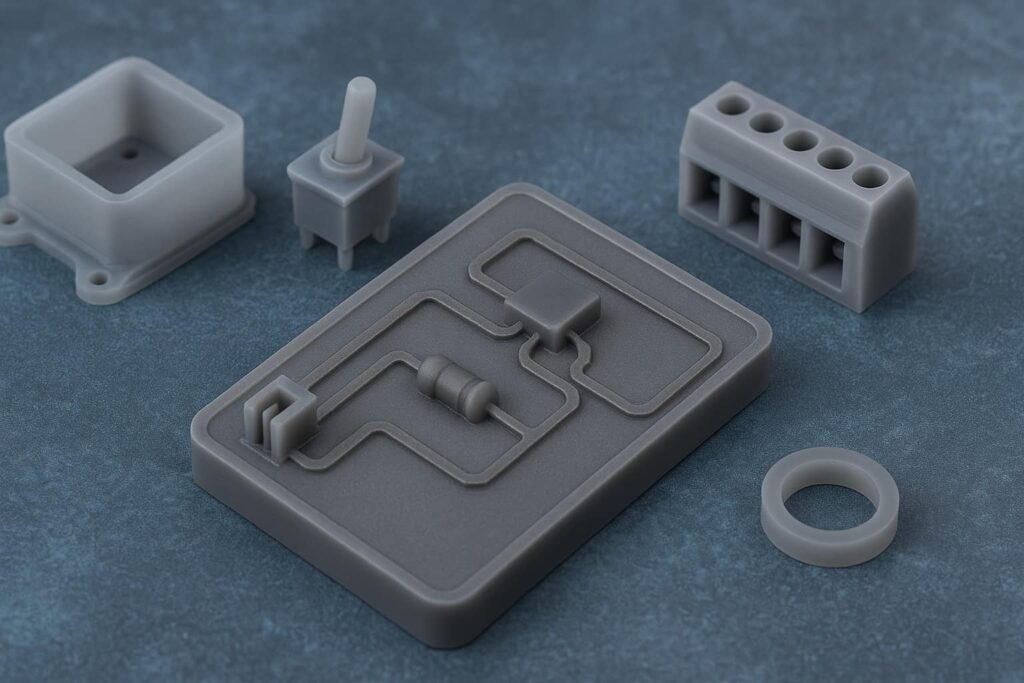

So, while resin is fantastic for creating non-conductive parts like custom enclosures or sensor mounts, printing something that actually carries current is a whole different story.

Yes, but it’s still very experimental.

There are conductive resins on the market, typically filled with carbon or silver particles to allow some level of conductivity. However, compared to metal, their conductivity is very low.

What this means:

The technology is still in its infancy, but it’s improving. Researchers are working on improving both the conductivity and durability of these resins.

Even if conductive resin has its limits, resin printing still plays a huge role in supporting electronics:

Design and print custom-fit housings for PCBs, batteries, and sensors. Resin is great for small, precise designs — especially for compact IoT devices.

Standard resins have high dielectric strength, making them ideal for non-conductive parts like switch holders or wire separators.

One common hack: print your resin part, then embed wires or conductive materials manually. This hybrid approach allows for functional prototypes or hobby electronics.

Want to add LEDs or light sensors? Transparent resin helps create sleek, illuminated effects. Flexible resin is also useful for tactile buttons or wearable devices.

While resin printing has its perks, it’s not perfect — especially for electronics:

So, while you can build great supporting structures, resin isn’t quite ready to replace copper traces or traditional PCB materials — yet.

The future looks promising. Here’s what’s on the horizon:

These innovations are gradually pushing the boundary of what resin 3D printing can do in the electrical field.

So, can you 3D print electrical components with resin?

That said, resin 3D printing is an amazing tool for electronics design and prototyping, especially when used in combination with traditional electronic assembly.

As material science and 3D printer tech continue to advance, we’re likely to see even more exciting possibilities.