- +91 8055996347

- info@3dreality.in

- Chapru nagar square, CA road, Nagpur, Maharashtra-440008

In the world of engineering, ideas often start as sketches on a piece of paper or complex models on a computer screen. But the journey from design to a functional part has traditionally been long, costly, and full of trial and error.

What if you could hold your idea in your hands within hours instead of months?

That’s exactly what 3D printing is doing for engineers today—it’s turning imagination into reality at an unprecedented speed.

Imagine you’ve just completed a revolutionary design for a custom gearbox or a lightweight drone frame. In the past, creating a prototype meant outsourcing it to a manufacturer, waiting weeks, and hoping that the part returned matched your vision.

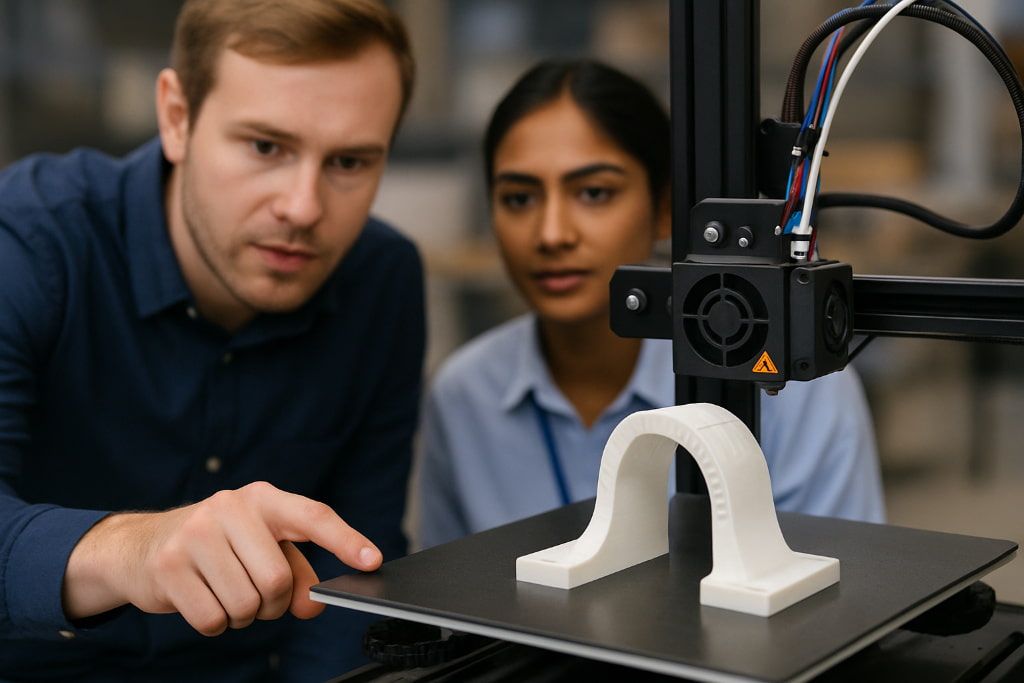

With 3D printing, that long wait is replaced by an almost magical moment—you send your design to the printer, and within hours, you’re holding the first tangible version of your idea.

This immediate feedback loop changes everything. Engineers can test, tweak, and perfect their designs at lightning speed, eliminating bottlenecks that once slowed innovation to a crawl.

Precision isn’t a luxury in engineering—it’s survival. Even a millimeter of error can mean the difference between success and failure in mechanical parts.

Modern 3D printing technologies, such as SLS (Selective Laser Sintering) and SLA (Stereolithography), give engineers the power to create parts with incredibly fine details and tight tolerances.

At 3dreality, we’ve seen projects where engineers needed parts with complex internal channels for fluid flow, which would have been nearly impossible to machine using traditional methods. With 3D printing, it was not only possible—it was efficient, accurate, and cost-effective.

One of the most common questions engineers ask is: ‘But is it strong enough?’

The answer lies in the rapid evolution of 3D printing materials. Today, engineers can choose from tough industrial-grade polymers, carbon fiber-reinforced composites, and even metals like titanium and stainless steel.

These materials aren’t just for show—they’re functional.

Think about an aerospace engineer printing lightweight yet strong brackets for a spacecraft or an automotive designer creating heat-resistant engine components. The strength is real, and the possibilities are endless.

For years, 3D printing was seen mainly as a tool for rapid prototyping. But times have changed.

Today, engineers are moving beyond prototypes and directly producing end-use parts. These are components that go straight into machines, vehicles, or devices without any further manufacturing steps.

At 3dreality, we’ve worked with engineers who needed short production runs for custom machinery parts. Instead of setting up costly molds or tooling, we printed exactly what they needed—saving time, money, and reducing waste.

Perhaps the most exciting gift 3D printing offers to engineers is design freedom.

Traditional manufacturing comes with limitations—certain shapes are impossible to produce without extra processes. But in 3D printing, complexity is free.

Want an intricate lattice structure that’s both lightweight and strong? Done. Need a part with multiple moving sections printed in one go? Absolutely possible. The only real limit is the imagination of the engineer holding the mouse.

Every one of these success stories shares a common theme—speed, precision, and limitless creativity.

3D printing technology is evolving faster than ever. Soon, we’ll see multi-material printing where engineers can combine metals, plastics, and electronics into one seamless build. Imagine printing a functional drone with all its wiring, sensors, and frame in a single print job.

For engineers, the shift is clear: 3D printing is no longer just a tool—it’s a competitive advantage. Those who embrace it now will lead the charge in designing the future.

At 3dreality, we believe engineering is about solving problems in ways no one thought possible before.

With 3D printing, the distance between design and a fully functional part has never been shorter. The question is no longer “Can it be done?” but “How fast can we print it?”

So, whether you’re building the next breakthrough in aerospace or designing precision parts for robotics, remember—your next innovation could be just a print away.